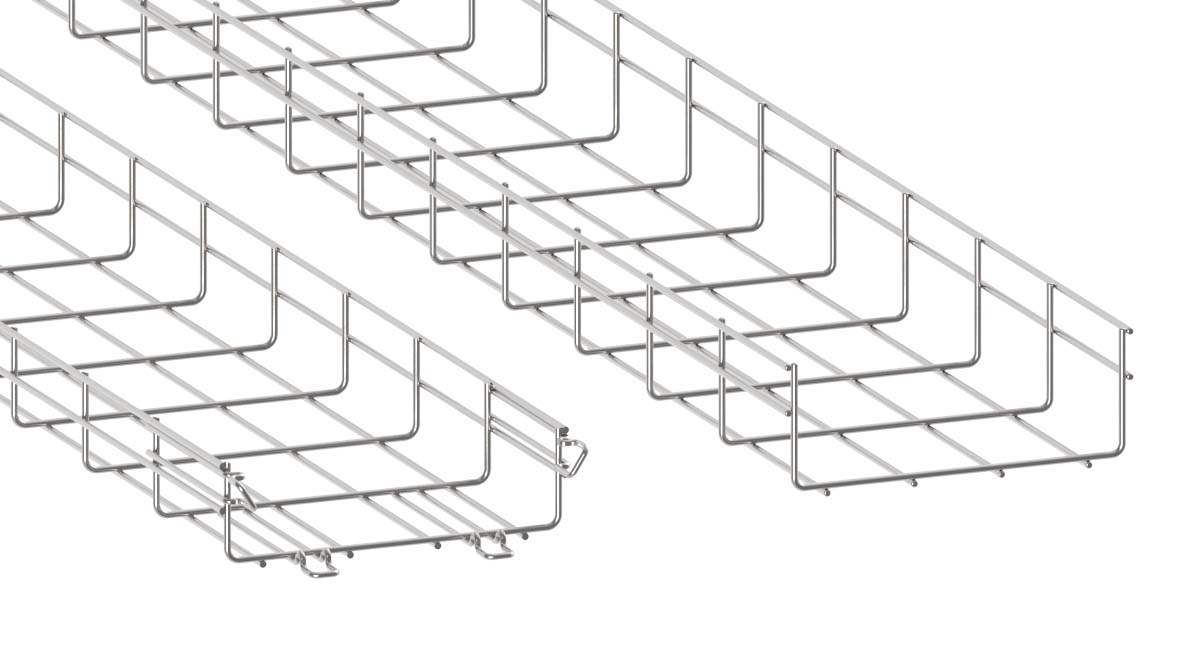

Maximum ventilation of cables

The mesh tray typology assures the maximum aeration inside the cable tray, allowing in this way also the use of cables for high current intensities.

By comparing the cooling that takes place on cables placed inside the mesh tray with other types, it may be observed that, with the same heating, the allowable current is 5-25% higher.

The weight is low

The peculiarity of this type of product puts it for sure among the lightest ones.

Here below the differences of weight in percentage are shown, compared with the other families of our products:

- Mesh tray VS cable tray with continuous bottom (e.g. FEMI 3 series): weight reduction from 20% to 50%.

- Mesh tray VS cable ladder (e.g. CZ 2 series): weight reduction from 25% to 70%.

Easiness of cable derivation

The shunting or branching of cables from the straight section can be carried out very easily without having to make installation changes to the edges of the channel, being able to use the mesh space of the mesh, preferably by applying our dedicated quick-fit accessories.

Simple installation and creation of accessories

The installation of the straight elements is quick and easy and in the case of the "MTC-Italy" series also very fast (only 5 seconds for 3 metres of route); moreover, with the straight elements alone, the installer can easily create various types of bends, branches, drop-offs and all sorts of complementary elements that best suit the characteristics of the system layout. In fact, with the use of a manual or motorised shear (it is advisable to use a shear with inclined blades) and universal clamps, the straight elements can be adapted to even the most tortuous routes. The choice and positioning of the inclined blades at the point where the cut is to be made makes it possible to obtain a clean cut, as close as possible to the intersection of the steel wires. In the case of hot-dip galvanised mesh, the protective layer of zinc will be partly dragged over the cut, favouring the creation of a galvanic couple which will protect the surface of the cut rod, although it is recommended to apply liquid zinc to the cut section with a small brush.

Compliance with regulations

The system is manufactured in conformity with the IEC 61537 European norm and with the American (Canadian) NEMA VE 1 (CSA C22.2 No. 126.1), all of international value. It has the CE and IMQ marking. Fire resistance certifications, or certifications for installation in seismic environments or specific certifications required by the customer are also available.

The inspection of cables is very easy

Thanks to the meshes of the tray, the cable inspection is much easier even for the possible insertion of control instruments on the cables themselves.

Washing and hygiene

Because of the way this type of cable carrier system is made, it is particularly suitable for use in foodstuffs and on board machines, where it is necessary to sanitise and wash the entire environment on a daily basis. It is the opposite of the IP44 solution, i.e. waterproof.